Altrad UK: Pioneering Scaffold Design with Technology and Innovation

Altrad is a global leader in scaffolding and industrial services, revolutionising the way scaffolding is designed, constructed, and delivered. Focused on efficiency, safety, and innovation, Altrad is reshaping the future of scaffold design by leveraging cutting-edge technologies like automation, artificial intelligence (AI), 3D modelling, and cloud-based collaboration.

Leading this transformation are Colin Murphy, Head of Technical Authorities at Altrad UK & Ireland, and Matthew Reeve, Senior Design Engineer. Their efforts are significantly reducing design time, enhancing collaboration, improving project accuracy, and driving down costs—while maintaining a sharp focus on safety.

Key Achievements:

💰 Reduced design time through automation and 3D modelling

🚀 Improved project timelines with real-time design updates and clash detection

📈 Increased project efficiency with cloud-based collaboration tools

🛠️ Enhanced safety by identifying design flaws before construction

Simplifying Scaffold Design with Automation

Traditionally, scaffold design has been a manual, labour-intensive process. Engineers had to manually calculate load capacities, communicate with clients, and frequently make revisions. This process is time consuming and requires meticulous detail.

By automating key aspects of scaffold design, Altrad has significantly reduced the time spent on design and improved its accuracy. This allows engineers to focus on more complex design challenges rather than repetitive tasks.

Colin Murphy explains, "By automating repetitive tasks, we’re able to free up time for more complex design challenges."

The Results:

- Faster design processes: Tasks that once took days now take only hours.

- Reduced costs: Lower labour expenses and overhead.

- Improved accuracy: Automated calculations reduce human errors.

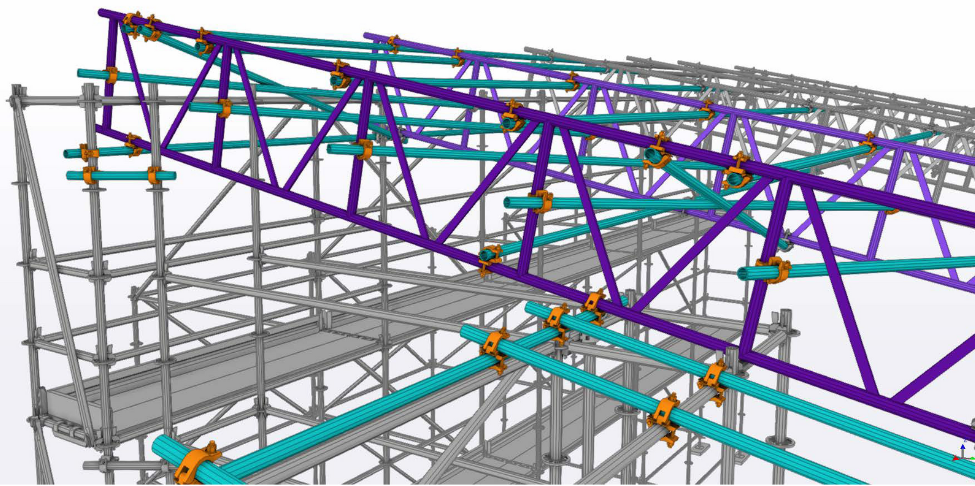

Accelerating Projects with 3D Modelling, Laser Scanning, and Clash Detection

Altrad has elevated scaffold design with the integration of 3D modelling. By creating interactive, visual representations of scaffolds, Altrad allows clients to fully review the design before construction begins. This approach reduces misunderstandings and prevents rework, ensuring that the final product matches expectations.

Murphy states, "The limitation to working in 2D is that a client can never really tell what it’s going to be like until it’s been built, and that alone creates the risk of complications and rework."

Additionally, Altrad uses laser scanning technology to create precise digital models of the project site, ensuring scaffolding aligns perfectly with real-world conditions. By pairing this with ScaffPlan's intelligent clash detection, the team identifies potential issues before they arise—ensuring the scaffold fits with millimetre precision.

Matthew Reeve notes, “3D models give everyone involved a clear picture of the scaffold layout. It reduces misunderstandings and makes client sign-offs smoother.”

The Results:

- Real-time updates: Teams can make changes instantly.

- Precision fit: Laser scanning ensures accurate alignment with site conditions.

- Fewer revisions: A 20% reduction in costly site adjustments.

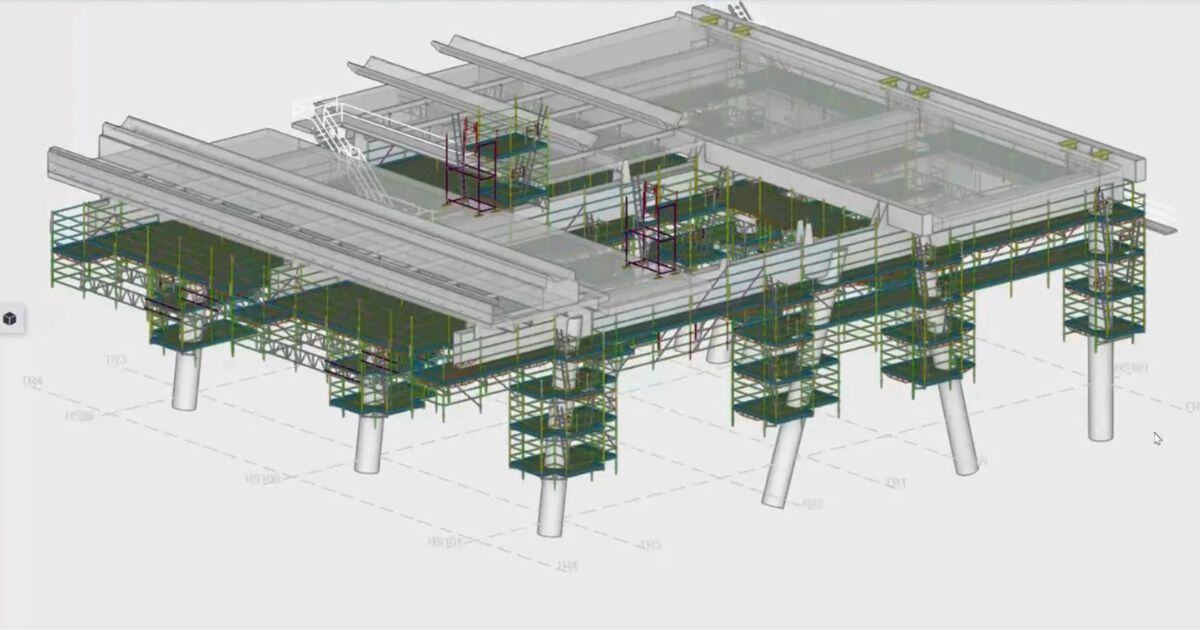

Cloud-Based Collaboration: Meeting Client Demands in Real Time

Modern clients expect more than static blueprints—they demand detailed, interactive 3D models before construction even begins. Altrad has embraced this shift by utilizing cloud-based platforms like Trimble Connect, allowing real-time collaboration between designers, engineers, and clients.

Reeve explains, “We’re using cloud-based storage to securely share designs with anyone. Site supervisors can access 3D models on-site, spin them around, and make live comments. It’s a game-changer for collaboration.”

The Results:

- Real-time collaboration: Teams can work together seamlessly from any location.

- Fewer delays: Instant feedback accelerates decision-making.

- Transparency: Clients have full visibility of progress and can provide immediate feedback.

The Future of Scaffold Design: A Digital-First Industry

As the scaffolding industry evolves into a more digital-first environment, Altrad remains at the forefront of this transformation. According to Murphy, “We’ve trained everyone from scaffolders to engineers to graduates in using these tools. It’s tailored to scaffolding, so the transition has been smooth.”

He further states, “The future is about working smarter, not harder. Clients will expect 3D models, and site teams will soon ask, ‘Where’s my 3D model?’ It’s far more collaborative, and it’s the future.”

By adopting these advanced technologies, Altrad is reshaping the scaffolding industry, making projects more efficient, safer, and collaborative. By leveraging automation, 3D modelling, laser scanning, and cloud-based collaboration, their team is reducing design time, cutting costs, improving accuracy, and meeting the evolving needs of clients.

|

💡 Want to learn more about Altrad’s digital transformation? — Visit https://www.altrad.com/en/ or connect with them on LinkedIn. |